what is 3D Printing ?

When talking about 3D printing technologies, it was first introduced to the world by Chuck Hull in 1983. During that time, there was no such thing as Rapid Prototyping (creating a concept model) let alone creating a functional model. Which meant creating a concept model took months and thousands of dollars to make. When designers and engineers were using Computer Aided Design (CAD) software – there was no way of transferring that knowledge directly and making a final. Chuck could lay foundation to fill the gap between software and hardware. The file format stl, which was developed by them, is still in use today.

3D printing is an additive manufacturing process used to create a three dimensional object. The virtual object is horizontally sliced into thin layers in a computer software and each of these layers are successively printed one on top of the other to form the final 3D object in the 3D printer. Here are some of the techniques used in 3D printing.

A layer of powder is placed and using a laser, the necessary parts are heated – causing the powder to fuse together. A successive layer of powder is added on top using a roller and the steps are repeated. The unfused powder that remains acts as a support for the coming layers.

For each sliced layer of the 3D object – tiny droplets of build material and support material is placed (similar to an ink jet printer) and using a UV light the build material is fused. The platform which holds the layers lowers – making room for the new layer.

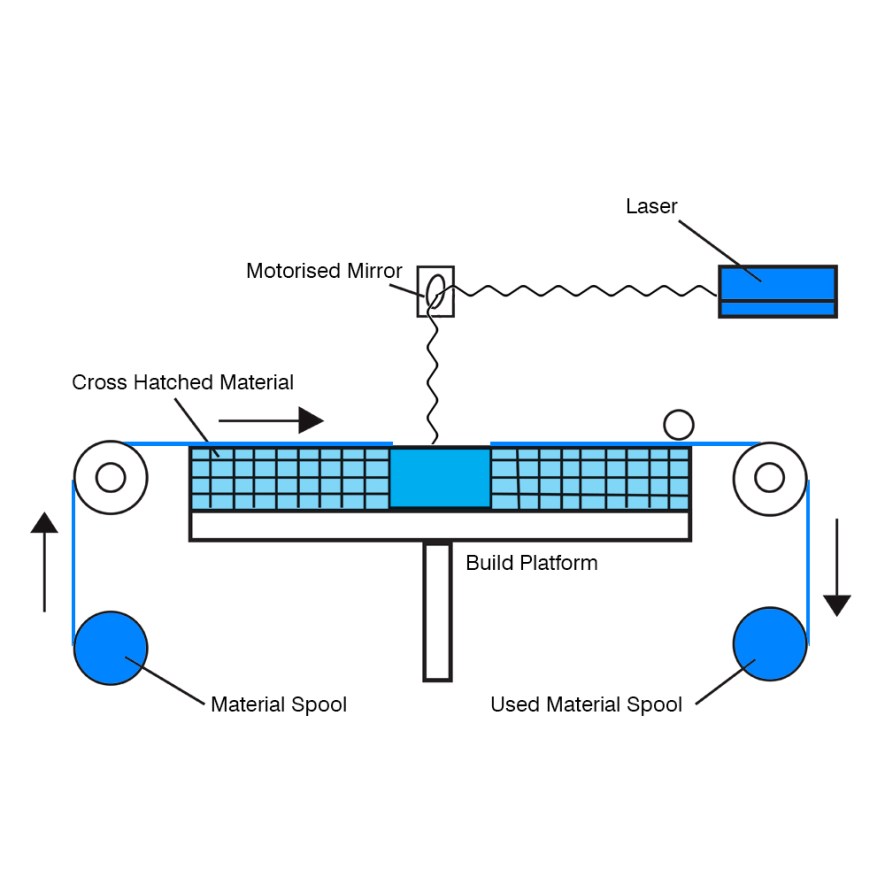

Sheets or ribbons of metal are bound together using ultrasonic welding. The required shape is then cut from the layer by laser or knife and the next layer is added. This method can also be used to fuse different types of metals.